The Power of China Plastic Injection Mold in Modern Manufacturing

The landscape of manufacturing continues to evolve, with China plastic injection mold technology leading the way in innovation and efficiency. This comprehensive guide explores the intricacies of plastic injection molding, emphasizing its critical role in the metal fabrication industry and its wide-ranging applications. So, whether you’re a seasoned manufacturer or new to the world of industrial processes, understanding the importance of this technology is essential.

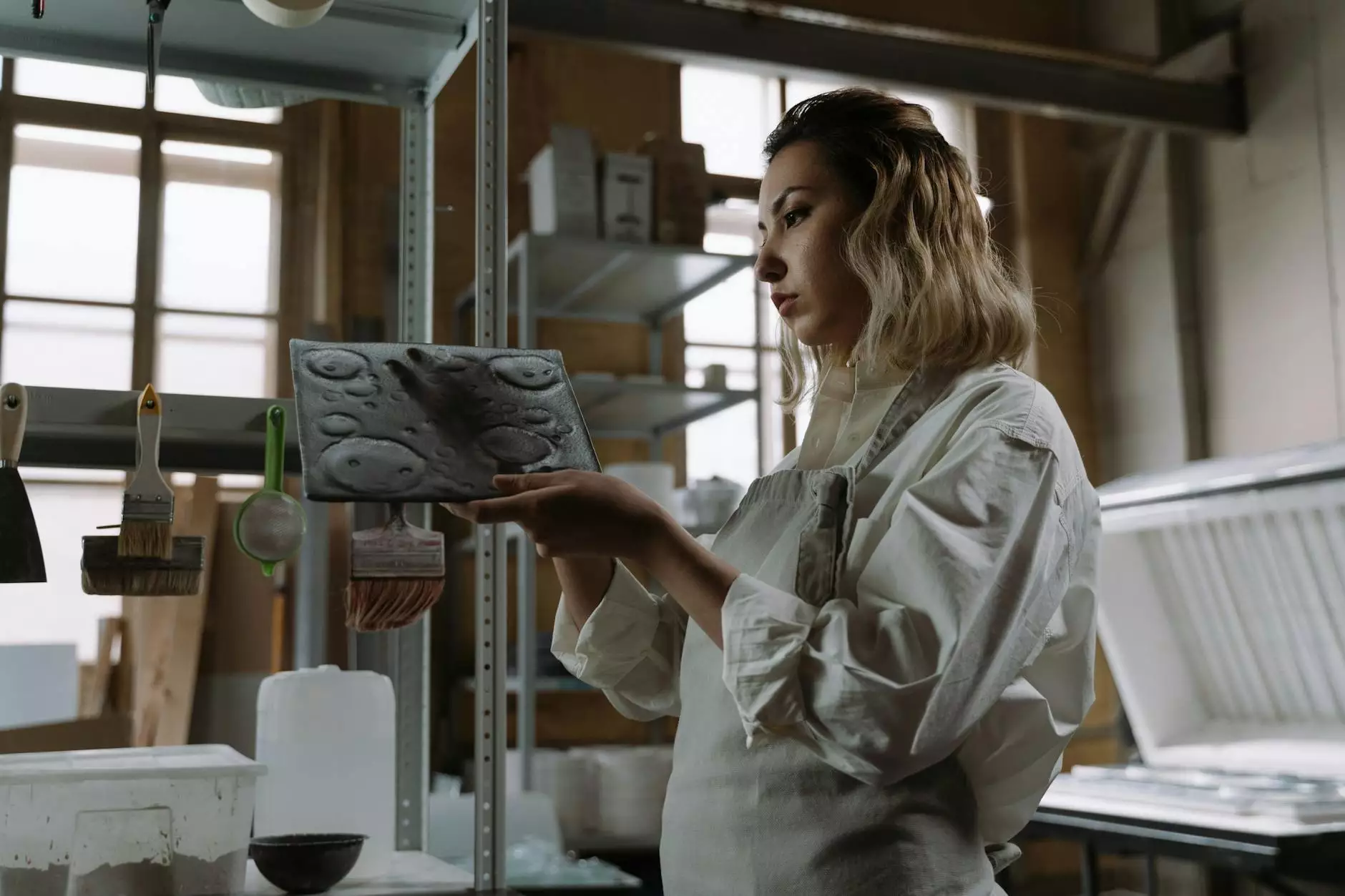

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process that produces parts by injecting molten material into a mold. This method is particularly effective for creating complex shapes with high precision and can be applied across various industries.

Key Components of the Injection Molding Process

- Injection Unit: The system that melts and injects the plastic into the mold.

- Clamping Unit: The component that holds the mold closed during injection.

- Mold: The cavity or form that shapes the injected material into the desired part.

- Trim and Eject System: Mechanisms that remove the finished part from the mold after cooling.

The Genesis of China Plastic Injection Mold

China has emerged as a global leader in plastic injection mold manufacturing, fueled by rapid advancements in technology, a robust skilled workforce, and competitive pricing. The evolution from basic plastic molding techniques to sophisticated, high-precision operations has positioned Chinese manufacturers at the forefront of this industry.

Advantages of Sourcing from China

Choosing to utilize China plastic injection mold services comes with several advantages, including:

- Cost Efficiency: Lower labor and production costs make it an economical choice for businesses worldwide.

- Scalability: Chinese manufacturers can accommodate both small and large production runs with ease, ensuring flexibility in order sizes.

- Advanced Technologies: Continuous investment in cutting-edge technology leads to enhanced precision and product quality.

- Expertise and Experience: With years of experience in the field, Chinese companies have refined their processes to deliver superior quality products.

Applications of China Plastic Injection Mold in Metal Fabrication

The integration of plastic injection molding into metal fabrication processes has revolutionized manufacturing approaches. Here are some notable applications:

1. Automotive Industry

In the automotive sector, plastic components created through injection molding contribute significantly to lightweight designs, enhancing fuel efficiency and performance. From dashboard panels to intricate engine components, the versatility of molded parts cannot be overstated.

2. Consumer Electronics

With the need for streamlined designs in consumer electronics, injection molded parts are prevalent in devices such as smartphones, tablets, and wearables. The precision of these components ensures functionality while maintaining aesthetic appeal.

3. Medical Devices

China’s capabilities in producing high-quality medical devices through plastic injection molding are unparalleled. With rigorous quality standards, the industry relies heavily on these processes for items like syringes, surgical tools, and implantable devices.

Choosing the Right Injection Molding Partner in China

Partnering with the right manufacturer is crucial for obtaining high-quality China plastic injection mold products. Here are essential factors to consider:

1. Expertise and Reputation

Research the manufacturer's history, testimonials, and case studies. A reputable company will have a proven track record of delivering quality products on time.

2. Technological Capabilities

Ensure the manufacturer employs the latest technologies in their injection molding processes. Advanced equipment often translates to higher precision and better quality control.

3. Communication and Support

Effective communication is vital for smooth operations. Choose a partner that offers exceptional customer service and responsiveness.

4. Quality Assurance Processes

Understand the quality control measures implemented by the manufacturer. Certifications such as ISO can be indicators of a commitment to maintaining high standards.

The Future of China Plastic Injection Mold

The future of plastic injection molding in China looks promising as advancements in technology and sustainable practices emerge. Here are some trends to watch:

1. Sustainability Initiatives

As global awareness of environmental issues grows, manufacturers in China are increasingly adopting eco-friendly practices. This includes using recyclable materials and improving energy efficiency in their production processes.

2. Automation and Smart Manufacturing

Automation and Industry 4.0 technologies are transforming the injection molding landscape. Smart factories equipped with IoT devices are improving efficiency, reducing waste, and enhancing production capabilities significantly.

3. Customization and Personalization

The ability to customize products is becoming more critical. Manufacturers in China are investing in flexible technologies that allow for personalized production, catering to niche markets and consumer preferences.

Conclusion

The impact of China plastic injection mold technology on global manufacturing cannot be overstated. Its advantages in cost-efficiency, precision, and versatility make it an invaluable asset in various industries. As the landscape continues to evolve, staying informed about advancements and choosing the right manufacturing partners will be essential for businesses aiming to leverage these benefits. By integrating high-quality plastic injection molded parts, companies can enhance their product offerings, streamline their operations, and remain competitive in an ever-changing market.

Call to Action

For businesses looking to harness the power of China plastic injection mold technology, consider partnering with leading manufacturers. Explore options with deepmould.net, where quality meets innovation for exceptional metal fabrication solutions.